Front anti-reflective coatings make a significant contribution to performance and energy yield in photovoltaic modules

According to the Fraunhofer-Institute for Solar Energy Systems ISE, photovoltaics will play a central role in our sustainable energy future. With an electricity generation of 46 TWh, it already covered approx. 8.7% of net electricity consumption in Germany in 2018.

The optical transmission, reflection and absorption of coplanar glass plates is strongly influenced by coatings and surface structures. Material properties and deposition processes must be precisely controlled to achieve the desired spectral properties. Anti-reflective coatings (ARC) for solar modules have to ensure maximum transmission in certain ranges of the light spectrum. Typical reflection losses at the raw glass-air interface of a solar module are about 4%. As the industry is on the way to higher efficiencies, AR coatings for front screens of solar modules will gain in importance. It is estimated that more than 70% of silicon photovoltaic modules today are supplied with ARC front glasses. (Source: Fraunhofer Center for Silicon Photovoltaics CSP)

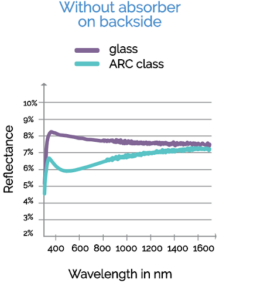

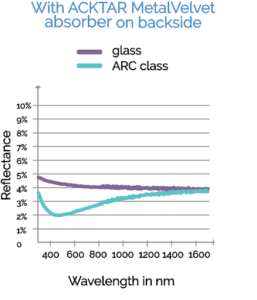

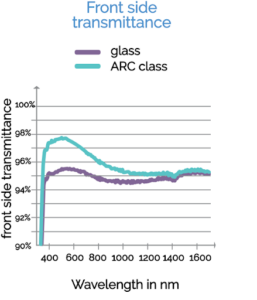

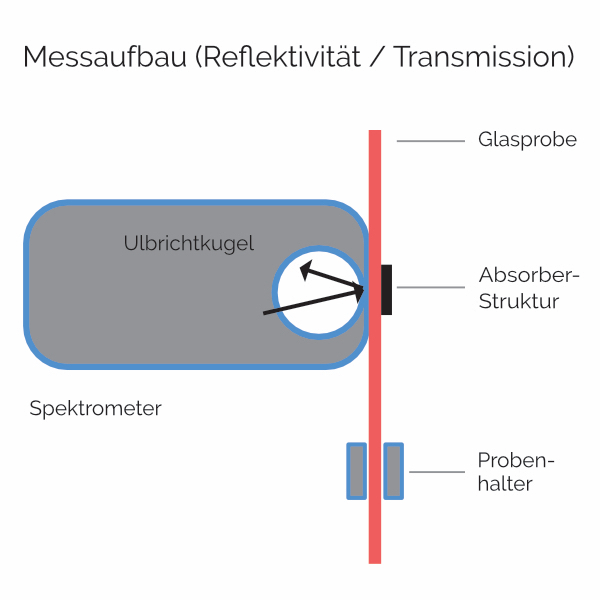

But, ARC degradation and abrasion may lead to long-term losses in optical performance. In order to quantify these losses and benchmark various AR coatings before and after abrasion testing, a research team of Fraunhofer Center for Silicon-Photovoltaics CSP, Halle (Saale) and Anhalt University of Applied Sciences, Köthen (Anhalt): I. Klemens, C. Pfau, P.-T. Miclea, S. Krause, C. Hagendorf, has carried out optical spectroscopy measurements that allow an evaluation of the ARC front side independent of the absorption of the glass substrate and the internal reflections from the back side. Here you can find the complete paper, which presents methodology for the quantitative measurement of the frontal ARC performance and its influence on the optical transmittance from a simple reflection spectroscopy measurement on large glass sheets. The absorber structure applied in the measurement setup is our ACKTAR MetalVelvetTM film with extremely low hemispherical reflectance to suppress internal back side reflections and scattering light within the glass substrate at a wide bandwidth (UV-VIS-NIR).

Measurement setup for “Quantification of abrasion-induced ARC transmission losses using reflection spectroscopy.

Measurement results